| Header MobilePalletizing 2024 |

| Leitsatz Palletizing |

PLUG & PRODUCE AUTOMATION: COBOT PALLETIZING

| Leitsatz Palletizing Resp B. Tablet |

PLUG & PRODUCE AUTOMATION: COBOT PALLETIZING

| Leitsatz Palletizing Resp Bl Smart |

PLUG & PRODUCE AUTOMATION: COBOT PALLETIZING

| Text-Einleitung 1a MobilePalletizing 2024 |

The way we work is changing. In this context, we have given a lot of thought to how we can make our contribution to keeping your production competitive and strengthening the industrial location in the long term.

Let's do this together! To actively shape the future of work: for more attractive workplaces, healthier employees and more efficient processes. Let's simply start where the challenges are lowest and the impact is most effective - with the automation of production logistics customized to your processes.

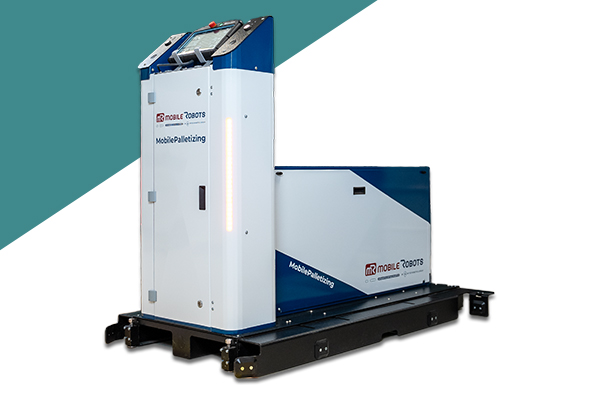

| Produktbild Palletizing 1 |

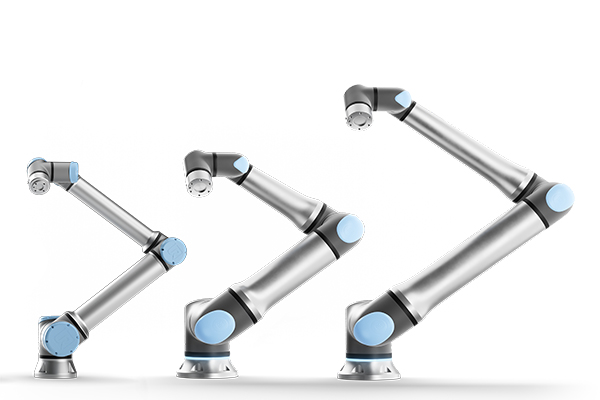

| Produktbild Palletizing 2 |

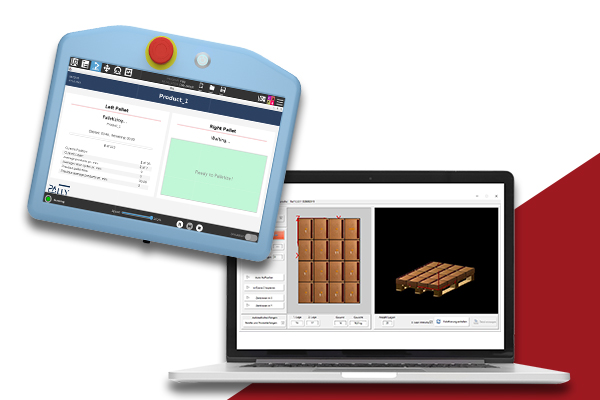

| Produktbild Palletizing 3 |

| Text-Einleitung 2a MobilePalletizing 2024 |

A NEW APPROACH TO EFFICIENCY ALSO FOR YOUR INDUSTRY SECTOR!

So that your valuable employees can concentrate on the really important, value-adding tasks, why not simply let collaborative robotics take care of intralogistics tasks? No matter what sector you work in - our latest configurable Cobot palletizing system is always flexibly designed to meet your requirements and tailored precisely to your processes.

MOBILE PALLETIZING WITH COBOTS

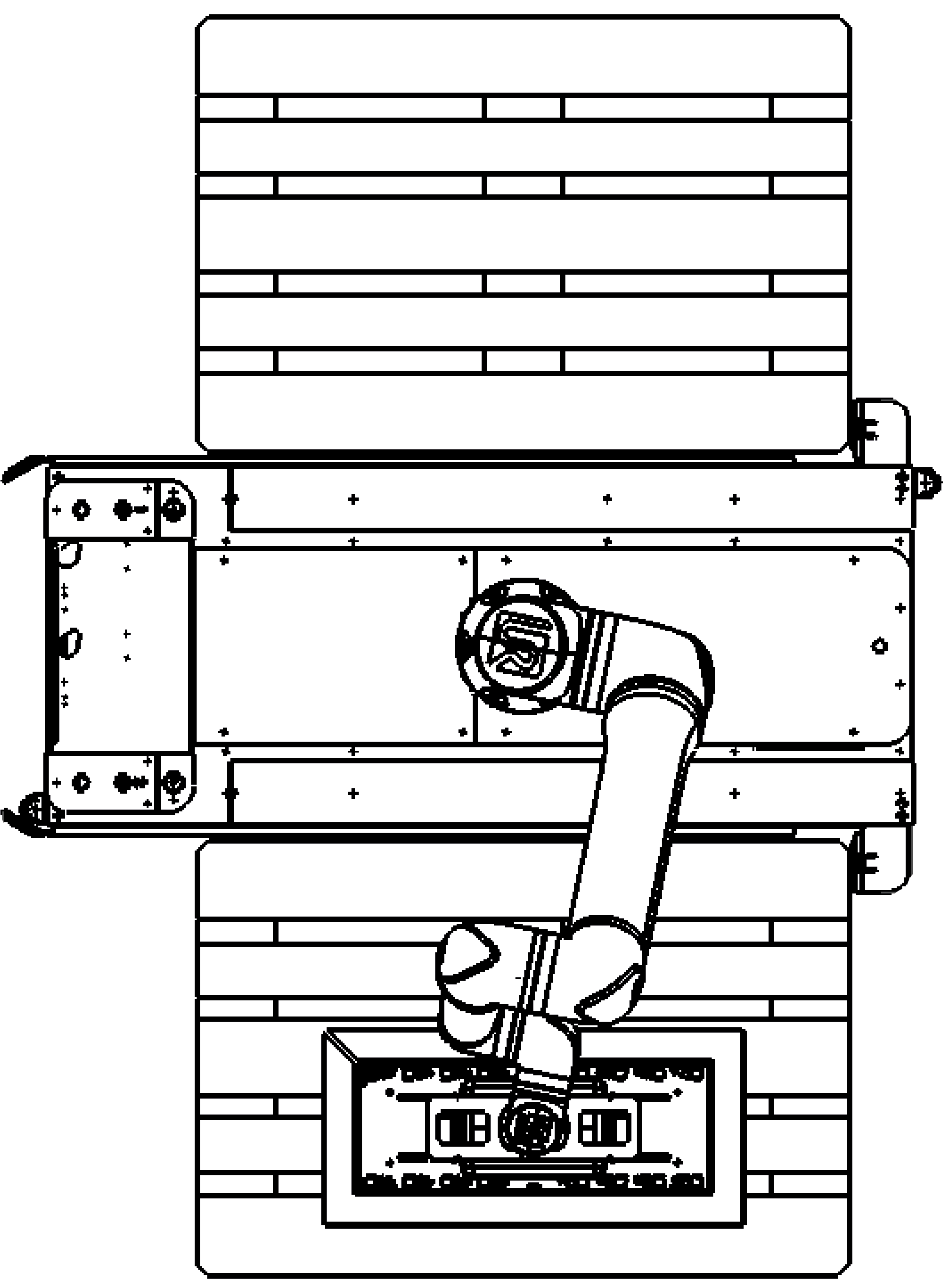

| Palletizer-Komponenten 2024 I |

| Palletizer-Komponenten 2024 II |

| Palletizer-Komponenten 2024 III |

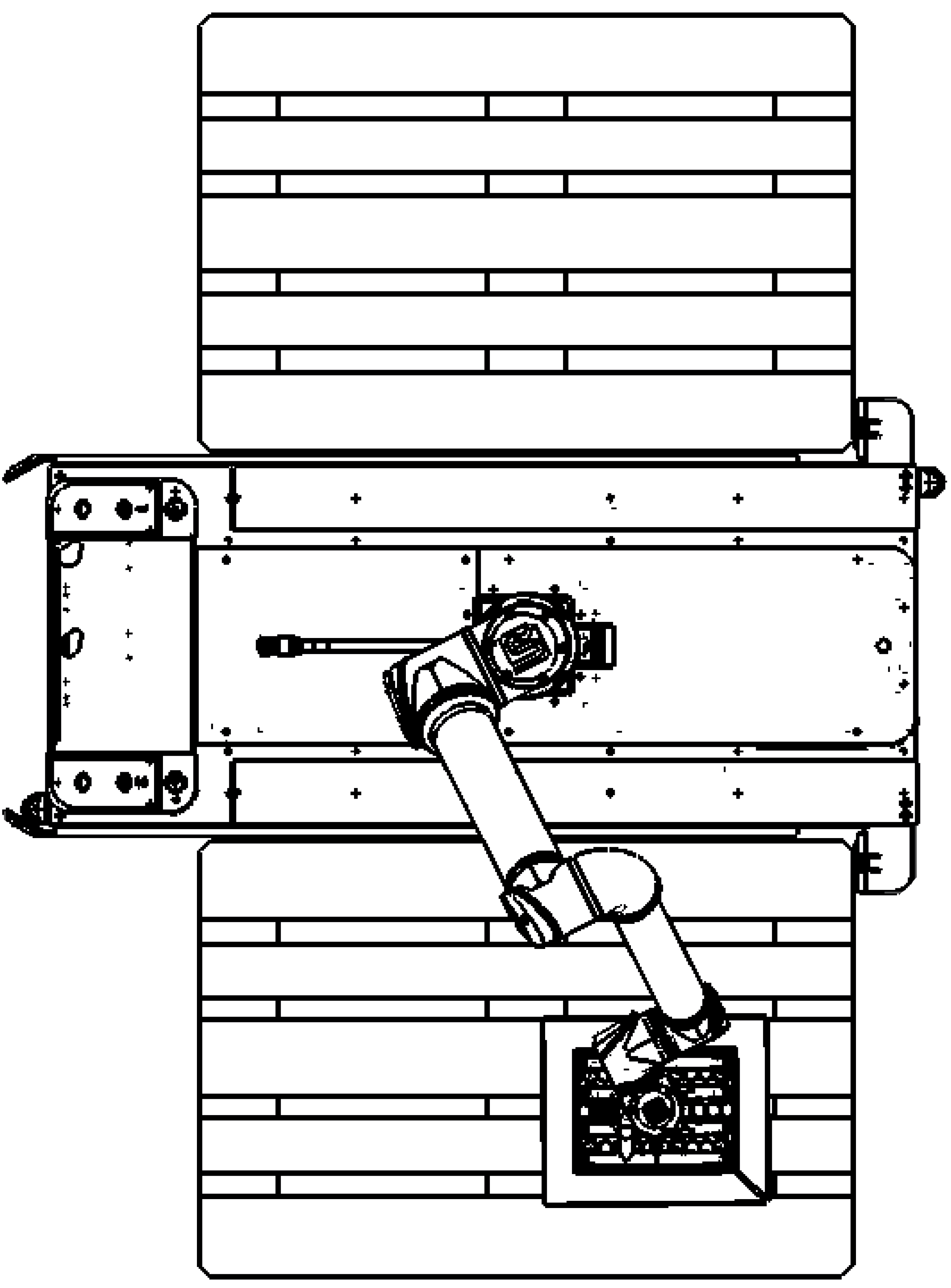

| Palletizer-Komponenten 2024 IV |

| Text-Einleitung 2b MobilePalletizing 2024 |

The MobilePalletizing system by mR MOBILE ROBOTS essentially consists of a control cabinet unit with control panel and a collaborative lightweight robot from Universal Robots - in the UR10, UR20 or UR30 version - which operates two pallet bays with a freely configurable end-of-arm tool. The intuitive controls and user-friendly software interfaces make handling child's play.

Thanks to the modular design of the three basic versions with maximum load capacities of 12.5 kg, 25 kg (New!) and 35 kg (New!), MobilePalletizing can be individually upgraded using peripherals and accessories and can therefore be used across all industrial sectors. This provides you with a particularly safe, simple and, last but not least, very effective "plug & palletizing" automation system. Proven in use and fully customized to your requirements.

Make no compromises when it comes to automation!

| MainValue Slider MobilePalletizing 2024 |

| Benefits Bulletpoints MobilePalletizing 2024 |

FACTS & BENEFITS

• 2 pallet bays

• Cross-industry suitability

• Compact design &

many options for flexible integration

• 3 variants with load capacities 12.5 to 35 kg

• Freely configurable end-of-arm tool (gripper)

• Variable system for easy changeovers

• Intuitive control for functional automation

| Logo white MobilePalletizing |

| Branchen-Icons MobilePalletizing 2024 |

![]()

| Branchen-Icons Text MobilePalletizing 2024 |

Thanks to its modular structure, MobilePalletizing can be individually configured and used in a wide variety of industries.

| Parallax-Slider Palletizing 2024 |

| Techn. Daten Headline |

TECHNICAL DATA

| Techn. Daten Palletizing UR10 |

VERSION UR10e*

PAYLOAD 12.5 KG

Max. Payload (Net/package): 12.5 kg (approx. 10 kg)

Robot Type: Universal Robots

UR10e Cobot

Dimensions Kit** (WxD): < 912 x 1,675 mm

Tare Weight Kit**: approx. 350 kg

Pallet Types: max. Standard EUR

Range of Cobot: 1,300 mm

Max. Stacking Height***: 2,000 mm

Temperature Range: 0 - 50 °C

| Techn. Daten Palletizing UR20 |

VERSION UR20*

PAYLOAD 25.0 KG (New!)

Max. Payload (Net/package): 25 kg (approx. 22 kg)

Robot Type: Universal Robots

UR20 Cobot

Dimensions Kit** (WxD): < 912 x 1,675 mm

Tare Weight Kit**: approx. 380 kg

Pallet Types: Standard EUR,

CP1, CP2

Range of Cobot: 1,750 mm

Max. Stacking Height***: 2,400 mm

Temperature Range: 0 - 50 °C

| Techn. Daten Palletizing UR30 |

VERSION UR30*

PAYLOAD 35.0 KG (New!)

Max. Payload (Net/package): 35 kg (approx. 32 kg)

Robot Type: Universal Robots

UR30 Cobot

Dimensions Kit** (WxD): < 912 x 1,675 mm

Tare Weight Kit**: approx. 380 kg

Pallet Types: max. Standard EUR

Range of Cobot: 1,300 mm

Max. Stacking Height***: 2,000 mm

Temperature Range: 0 - 50 °C

| Techn. Daten Palletizing Kit Ges. |

COMMON PARAMETERS ALL VERSIONS

Pallet locations: 2 - prepared for AGV/AMR connection; Power supply: 400V, 50 Hz, 16A; Compressed air: 6 bar (consumption dependent on gripper); Interface Kit: I/O, MODBUS, TCP, Emergency stop (In & Out), 2x digital output, 2x digital input, 1x analogue output, Power (230V or 400V) - freely available if no conveyor belt is combined - other interfaces optionally on request; Safety: KAT. 3 Pld, CE conformity, based on guideline TS 15066, power & force limitation (EN ISO 10218-1), tactile safety contact buffer (EOA); Cycle output: depending on product weight, pack image & pallet type 4-36 packs/min.

* Modification & errors excepted.

** Dimensions excl. conveyor belt & pallets, weight with lifting axis differing

*** Exact stacking hight depending on palletizing pattern, package dimensions & pallet type

| Lieferumfang & Info-Download Palletizing Kit |

SCOPE OF DELIVERY MobilePalletizing

1x Compact Palletizing Unit with switch cabinet & control desk

1x Cobot Universal Robots (at choice UR 10, UR 20 or UR 30)

1x End-of-Arm Tool at choice (e.g. soft areal vacuum gripper or mechanical gripper)

1x Tactile Safety Contact Buffer for gripper housing

1x Set flexible cable/hose guide for robot

1x Palletizing Software for free packing patterns & sort confectioning

| Headline Optionen MobilePalletizing |

CUSTOMIZED OPTIONS MobilePalletizing

| Palletizing-Opt1 |

| Palletizing-Opt.2 |

| Palletizing-Opt.3 |

| Text Optionen MobilePalletizing |

Customized or adjustable multiple grippers; End of Arm-Tool quick change system; conveyors (basic or accumulation roller version); telescopic lifting axis

in addition: image processing; machine signalling lights; safety scanner; OPC UA or Profinet interface; special stainless steel construction

| Call-to-Action MobilePalletizing 2024 |

BRING MobilePalletizing TO YOUR COMPANY:

CONTACT US!

Make an appointment now to plan your autonomous production logistics with mR MOBILE ROBOTS and let us talk about a customized integration of flexible Cobot palletizing in your company.

| Links / Impressum Resp Generell |

| Adress-Block / Copyright |

mR MOBILE ROBOTS & DAHL Robotics

are brands of

DAHL Automation GmbH

© 2017-2025 DAHL Automation GmbH

| Logo Exp. Center |

VISIT OUR COBOTS &

MOBILE ROBOTICS SHOWROOM

| Links / Impressum |

Contact

Contact